6015 Metal Fiber Laser Cutting Machine

Suitable for different metal materials

Auto focus Automatic edge searching

Multiple functions including cutting, carving, and marking

Intelligent display screen

Multiple languages

| Work Area | 6000x1500mm |

| Laser Source Power | 1500w / 2000w /3000w /6000w/12000W/20000W/30000W |

| Laser Source Brand | Raycus/MAX/Reci |

| Laser Head | Auto Focusing BM06K |

| Chiller | Hanli |

| Servo Motor | Delta / Fuji |

| Reducer | Beitto |

HY-6015 high-power laser cutting machine can handle large sheets of material, up to 6m in length and 1.5m in width. It is often used in industries that cut thicker sheets, such as steel structures, furniture processing, etc. It can cut faster and more accurately, making it a popular choice for industrial applications.

Specification

Auto-focus laser head

Crafted from premium materials using cutting-edge technology, the auto-focus laser head exemplifies strength and durability.

Its innovative design facilitates seamless “online” measurements throughout production, ensuring swift and precise measurements. This feature contributes to the overall accuracy and efficiency of the cutting process.

Ultra-large Work Area for Full Panel Cutting

The machine bed length and configuration we provide can be customized according to the specific needs of customers to meet the unique requirements of various industries for large workpiece processing. This flexibility is particularly suitable for batch processing of whole plates, which can greatly reduce the time required for plate change, thereby improving overall production efficiency.

The Laser Source

This advanced laser integrates an efficient water cooling system, realizes maintenance-free design, and greatly improves the stability and service life of the equipment. Its electro-optical conversion efficiency exceeds 25%, demonstrating its excellent high efficiency characteristics. At the same time, the laser also has high reliability and high performance, and can accurately and efficiently cope with complex processing needs such as cutting, welding, and drilling of various metal materials such as stainless steel, carbon steel, aluminum, and copper.

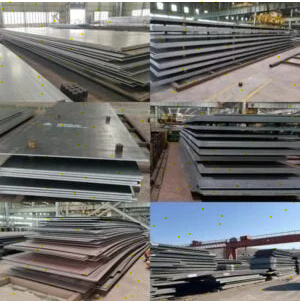

Product Applications

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel, Mild Steel Plate(tube), Carbon Steel, Alloy Steel Plate, Spring Steel, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc.Different cutting thickness depends on different laser power selection in sheet metal laser cutting machine.

Questions that you may be concerned about

All metals can be cut, including carbon steel, galvanized sheet, stainless steel, aluminum, copper, and so on. If you want to cut other materials, you can use our hybrid all-in-one machine.

First, in terms of configuration, we use well-known brands, and the configuration solutions we provide are the best choices after multiple rounds of testing to confirm the running-in effect of each component.

Secondly, in terms of machine installation and debugging, each of our machines will be debugged before leaving the factory. After installation, various system operation tests and cutting tests will be carried out to ensure that the machine performs well before leaving the factory. Commonly used parameter settings will also be preset for you during the cutting test. We will provide you with video calls or video shooting for testing.

The laser is guaranteed for two years, and the entire machine is guaranteed for three years.Lifetime maintenance service.

We also provide engineers to the factory for installation and training services for your employees. You only need to provide airfare and accommodation expenses.

Before delivery, we have wooden packaging protection, and will use steel welding base protection, which can protect the machine and make it convenient for you to pick up the goods with a forklift. If you have an agent in China, we can also help you deliver directly to your freight forwarder’s warehouse.

If want to become our first level agent, you must first ensure that you can sell at least $100000 worth of goods annually. We can offer you prices that other factories cannot offer you, giving you an absolute advantage.

If just want to sell our machines, you can contact our sales team.

SEND INQUIRY