Laser Pipe Cutting Machine

- Can be a variety of metal, and non-metallic materials for processing, especially for high hardness.

- High melting point, and brittle material marking more obvious advantages.

- Belongs to the non-contact processing, does not damage the product, has no tool wear, marking good quality.

- The laser beam is fine, the processing material consumption is small, and the processing heat influence area is small.

- High processing efficiency, the use of computer control, and easy-to-reach automation.

[maxbutton id=”1″ url=”#” text=”SEND INQUIRY” extraclass=”popup-field” ]

Description

Plate and tube integrated cutting machine

|

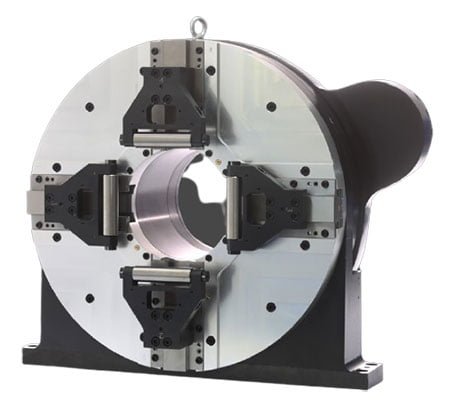

Smart chuck

Professional pipe cutting machine chuck, stable performance, strong clamping force, less waste, reduce waste, convenient regular on-site maintenance |

|

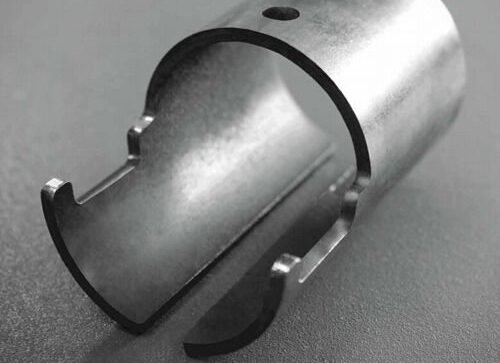

Professional processing of pipes

|

|

The Cast Iron Bed

Utilizing a custom cast iron bed with flake graphite and a minimum tensile strength of 200 MPa ensures robustness and durability. |

Product Applications

| MODEL | HY-Tp Series |

|---|---|

| POWER(OPTIONAL) | 1500w/2000w/3000W/6000W |

| PROCESSING FORMAT | 6M/7M/12M/customizable |

| MAXIMUM SPEED | 1.5G |

| MAXIMUM LINKAGE SPEED | 120m/min |

| REPEATED POSITIONING ACCURACY | ±0.03mm |

| TEMPERATURE AND HUMIDITY REQUIREMENTS | 0-45℃/35%-70% |

| Materials | Carbon steel, stainless steel, aluminum, copper, brass |

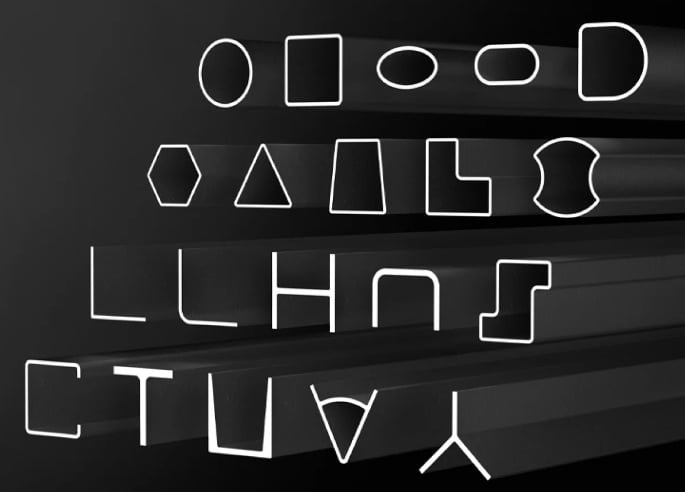

| Tube shapes | Round, rectangular, square and other standard profiles |

| Chuck size (optional) | 120/160/245/290/300/360mm |

| Processing range | Round max: 0-360 mm |

| Square max: 0-360 x 360 mm | |

| Circumscribed circle: less than 360 mm | |

| Maximum raw material length | 6000-12000 mm customizable |

| Maximum tube weight | 100-600kg(According to the chuck size) |

| Number of chucks | Single, double, triple |

|

|

|

Reviews

There are no reviews yet.