Laser Cleaning Machine

- Suitable for different metal materials

- Auto focus

- Automatic edge searching

- Automatic temperature adaptation

- Multiple functions including cutting, carving, and marking

- Intelligent display screen

- Multiple languages

[maxbutton id=”1″ url=”#” text=”SEND INQUIRY” extraclass=”popup-field” ]

Description

Fiber Laser Cleaning Machine

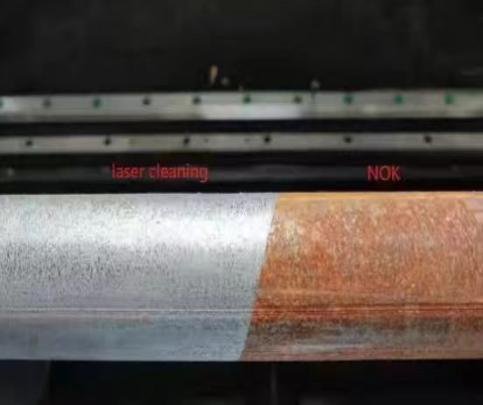

Laser cleaning machines use a focused beam of light to remove dirt, rust and other contaminants from a variety of surfaces. The main area of application for this technology is in the removal of rust from metals. The machines are non-contact, meaning they do not physically come into contact with the surface being cleaned, reducing the risk of damage or wear. They are also environmentally friendly and do not use chemicals or abrasives, making them a smart choice for industrial and commercial applications such as automotive, electronics and medical device manufacturing. Our range of laser cleaning machines is efficient, affordable and versatile. They can be used on metals, plastics, glass and ceramics, removing contaminants quickly and efficiently, saving time and labor compared to traditional cleaning methods.

Working principle:

Operation of laser cleaning is based on exposing a light beam to the surface. If there are no contaminations (for example rust), the laser beam is reflected. If there is corrosion, it absorbs the beam. Because of thermal energy of the laser, the strength of metal oxide molecules that form the rust decreases. They collapse, detach from the metal, melt, and evaporate.

[yrm_accordion id=”8″][/yrm_accordion]

Advantage

- High Precision: Laser cleaning machines can remove dirt, rust, and other contaminants with high precision and minimal damage to the underlying surface.

- Non-Contact Cleaning: Laser cleaning machines use a focused beam to remove contaminants without physical contact and reduce the risk of damage to the cleaned surface.

- Environmentally Friendly: Laser cleaning machines do not use chemicals or abrasives, making them an environmentally friendly alternative to traditional cleaning methods.

- Versatile: Laser cleaning machines can be used on a variety of surfaces, including metals, plastics, glass, and ceramics.

- Time Saving: Laser cleaning machines can quickly and effectively remove contaminants, saving time and labor compared to traditional cleaning methods.

- Cost-Effective: Laser cleaning machines can be a cost-effective alternative to traditional cleaning methods, especially for large areas and heavy cleaning tasks.

.

Specification

|

Cleaning HeadThe ergonomic and adjustable cleaning head allows for precise targeting of the laser beam, ensuring effective cleaning in hard-to-reach areas and on complex geometries. Its design minimizes operator fatigue and enhances control during the cleaning process. |

|

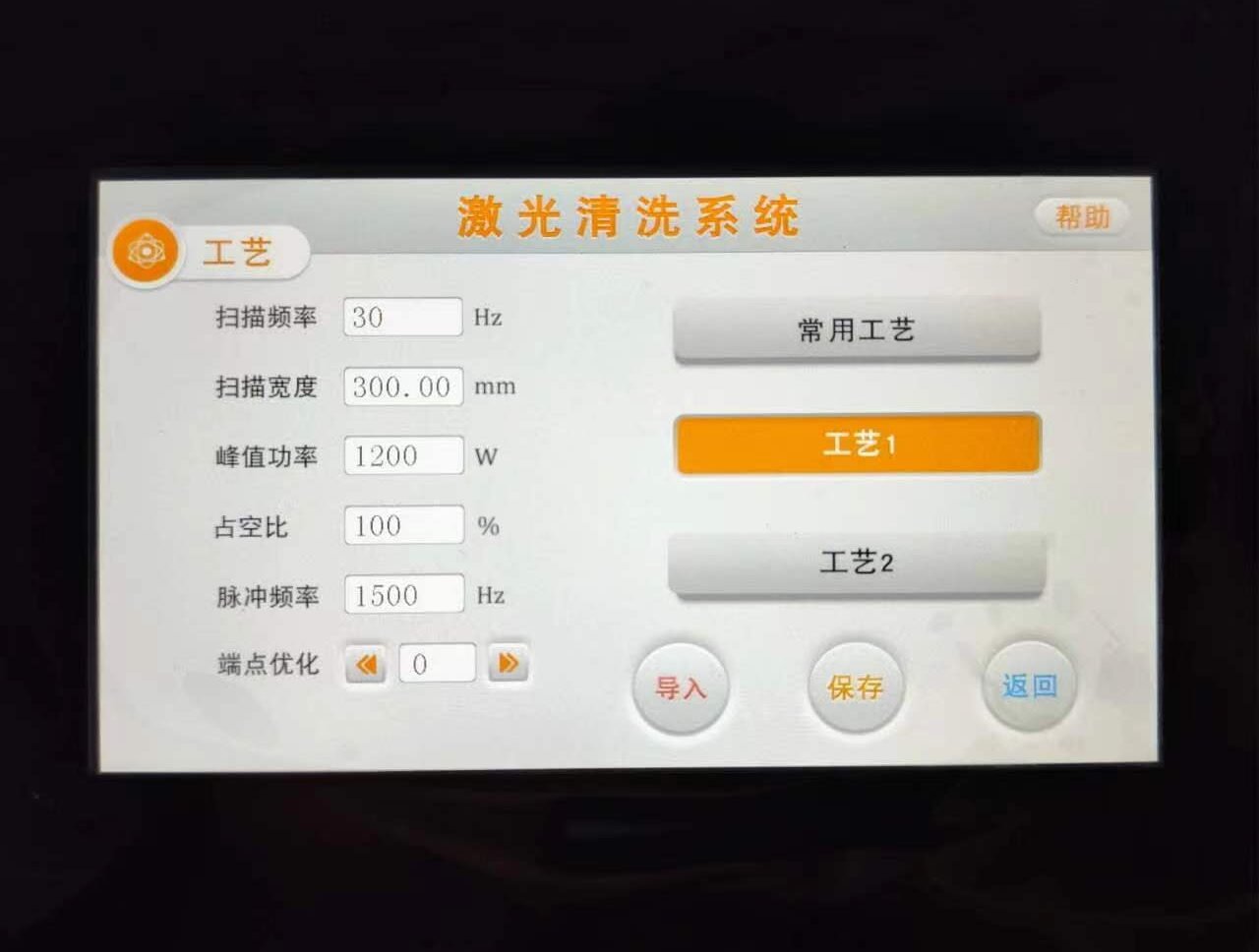

Control SystemThe advanced control system provides users with intuitive interfaces and customizable settings, enabling precise adjustments of laser parameters to match specific cleaning tasks. This ensures optimal results for different materials and levels of contamination. |

|

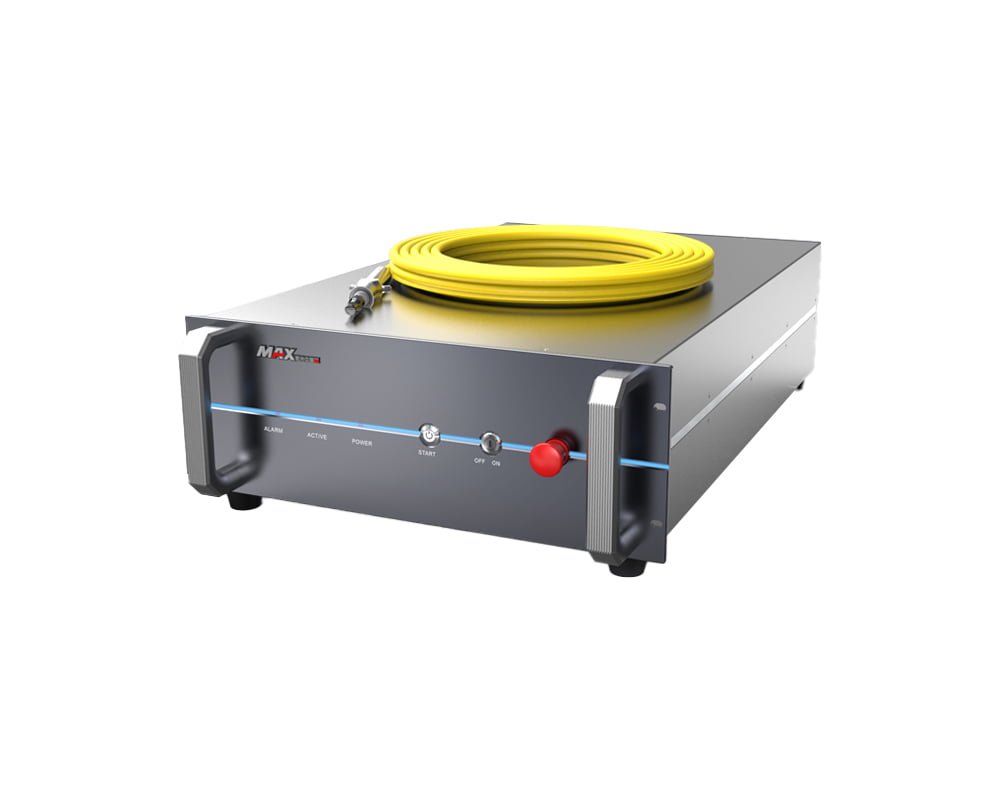

Laser SourceThe high-power laser source is the core of the cleaning machine, offering superior cleaning capabilities by effectively removing contaminants such as rust, paint, and coatings from various surfaces. It ensures precision and minimal damage to the underlying material. |

Product Applications

|

|

|

|

|

Hoysook fiber laser cleaning machine is an affordable, easy to use and versatile tool. This type of fiber laser cleaning machine is suitable for removing contaminants from the surface of stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titanium and other materials, and has been widely used in advertising, high-voltage/low-voltage electrical cabinet production, textile machinery parts, kitchen appliances, automobiles, machinery, elevators, electrical accessories, spring coil parts, subway line components and other industries. It is widely used in kitchen appliances, sheet metal cabinets, mechanical equipment, electronic equipment, lighting hardware, advertising signs, auto parts, fitness equipment and other metal products, sheet metal cutting and processing industries. Different materials and cleaning areas need to choose different power.

What materials can be cleaned with a laser?

Laser cleaning equipment is mainly used to remove pollutants from metal surfaces. It can also be used to clean non-metallic materials such as plastics, stone, ceramics and concrete.

With a laser cleaning machine, you can process:

- Small items: terminals, connectors, circuit boards, wires, anilox rollers. The laser can remove up to 1 mm of insulation;

- Precious items: jewelry, gemstones, coins, archaeological artifacts;

- Auto parts: engines, power-assisted bicycles, etc.

- Large components of various equipment, such as aircraft, rockets, military equipment, oil production and refining equipment, etc.

Reviews

There are no reviews yet.