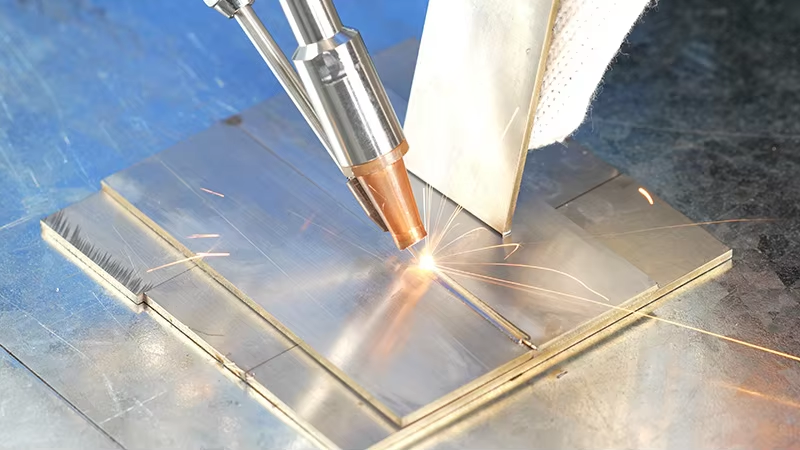

Laser Welding vs. Traditional Welding

Laser Welding: is a good choice for large manufacturing plants that often use welding to join metals. Laser welding is more versatile than traditional welding. For large manufacturing operations, the cost of a laser welding machine is negligible.

- TIG Welding

TIG welding is particularly suitable for small metal shops that need welding services occasionally. The process is less expensive than laser welding and is generally more compact. Changing the filler material rod is cheaper than purchasing a laser welding machine. If you need to weld different alloy metals, TIG welding may be more suitable for you.

- MIG Welding

One of the prominent disadvantages of laser welding compared to MIG welding is that it is expensive, but you have to know that laser welding is expensive for a reason, and its welding effect is better than MIG. If the work piece material is compatible with MIG welding, it can also produce good results. Therefore, if price is more important than surface effect, laser welding will not be a good choice. However, to weld complex materials such as luxury decorations, using MIG welding will only result in poor and fragile surface effects. It all depends on your final choice.

- SMAW Welding

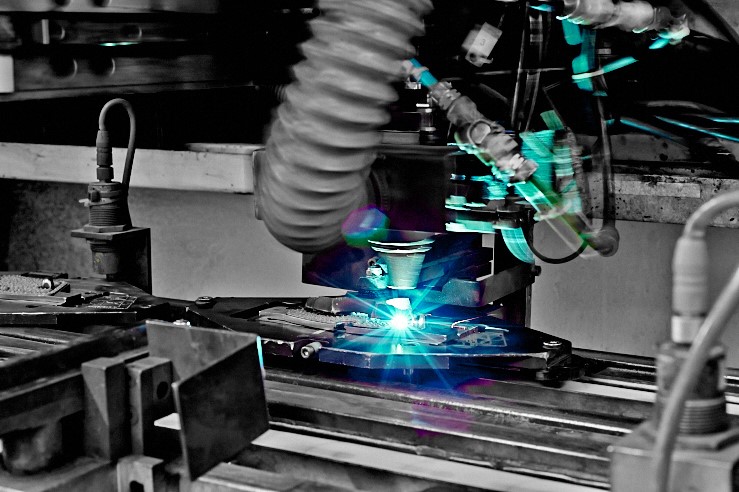

Laser welding is compared with SMAW welding. SMAW welding is particularly good at processing steel, stainless steel, alloys, etc. But laser can be applied to more materials, such as aluminum, titanium and other metal materials. SMAW is manually operated and runs slower than laser welding machines. Laser welding can provide focused energy at an amazing speed, which gives it an advantage in repetitive and large-scale tasks. And it is highly dependent on the welder’s skills. A person who has never had welding experience can weld a perfect weld with a laser welding machine.

- EBM Welding

The most obvious advantage of laser welding over EBM welding is that it does not require a vacuum chamber in its operation. Unlike the physical enclosure required for EBM welding, laser welding is more flexible. Laser welding also has simpler tooling requirements compared to EBM welding requirements. Since EBM welding requires more precise and unique components to work, laser welding is more scalable. There are many options for assembling parts. Therefore, laser welding is less expensive to construct and maintain than EBM welding.

- Gas Welding

Gas welding or oxyacetylene welding is a traditional welding method that relies on gas combustion to generate heat and melt the workpiece. Acetylene gas is the ignited fuel, and oxygen makes the flame burn hotter and longer. It is suitable for non-ferrous metals. But compared with laser welding, the welding effect is much worse.

- Brazing Welding

Brazing is a special metal connection method. Compared with laser welding, it has higher requirements for filler materials, which must have a lower melting point than the base material. It also requires extremely high temperature control capabilities to ensure that the joint is strong enough after welding. Otherwise, it will be misaligned or weak under high pressure, resulting in an inability to properly smooth the seam.

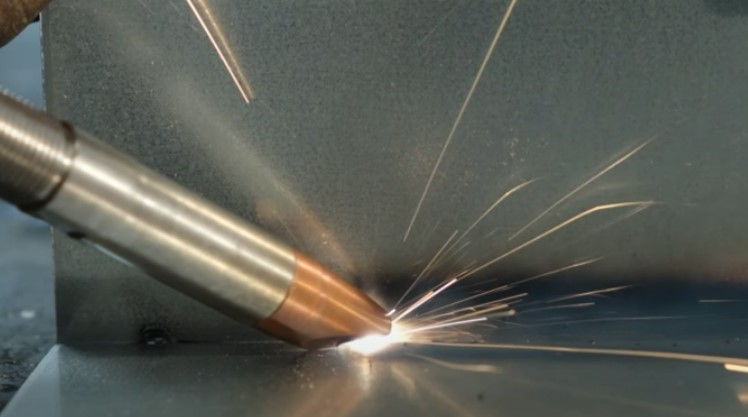

- PAW Welding

To weld an area, simply project a high-intensity laser beam onto a localized point. The beam generates heat. In PAW, a high-density plasma arc beam generates heat. The heat causes the metal to melt. The molten metal fills a gap or forms a connection between two materials. Laser technology can be used in conjunction with MIG welding if fusion welding is required. Other types of welding do not require plasma welding. It can weld deeper into the metal at a lower power input. A constant supply of inert tungsten gas is required. If tungsten gas is not available, other gases can also be used. In PAW, the inert gas forms a protective atmosphere around the weld pool. It can also be used indoors. No major precautions or laboratory environment are required. However, PAW must be performed in an environment that meets safety standards.

- RSW Welding

In terms of practicality, laser welding is far superior to RSW welding. First, RSW welding is only suitable for spot welding and nothing more. You cannot use it for continuous welding. In contrast, laser welding can perform both spot welding and continuous welding. RSW welding cannot handle workpieces thicker than 6 mm, which is another obstacle. It is particularly suitable for sheet metal processing. However, fiber lasers can easily handle sheet metal and thin and thick plates. Laser welding is much more precise than spot welding. This unique feature of laser technology is used in the medical industry, micromachining, jewelry making, etc.

Characteristics of water cooling and air cooling of laser welding machines

Water Cooling: as the name implies, uses water to remove heat through a heat exchanger (such as a water-cooled plate). Its working principle is simple: cold water from the chiller flows into the heat exchanger through a pipe, then flows out from another port and returns to the chiller through a pipe, and so on, constantly circulating to remove the heat from the laser. The water cooling system has a simple structure, is easy to maintain, has strong heat dissipation capacity, and good temperature uniformity. Using a chiller with higher cooling capacity can improve the cooling performance of the laser. At present, there are about 500 companies that integrate and sell handheld laser welding machines on the market, most of which use water cooling. However, water-cooled handheld laser welding machines require additional chillers and water, which greatly increases the overall size and weight of the equipment and limits its use environment.

Advantage:

- Excellent cooling efficiency: more suitable for long-term intensive use.

- Quieter operation: less noise compared to air-cooled systems.

- Function 4 in 1: ① Cutting – less than or equal to 3mm ② Welding ③ Cleaning ④ Cleaning welds

- Multiple power options: 1500W, 2000W, 3000W

- High welding thickness: up to 8mm

Disadvantages:

- Complexity: The more parts there are, the more potential failure points there are.

- Higher cost: relatively high maintenance costs due to more components.

Air Cooling: The difference between water-cooled and air-cooled laser welding machines lies in the cabinet. By replacing the original water-cooling with air-cooling, the weight of the whole machine is directly reduced to about 60kg. An adult can lift and move it with both hands, or push and pull it with both hands, which is convenient to carry and light. The integrated cabinet design is more compact and can be easily installed in ordinary cars, making outdoor operations possible. The equipment uses a three-phase 220V power supply, which has a wider range of usage scenarios. It can be handheld and can be easily operated even with zero experience. Air cooling allows operators to work continuously for 18 hours, which is sufficient for most usage situations.

Advantages:

- Simple: The fewer parts there are, the less chance there is of something going wrong.

- Cost-effective: Lowers initial investment and maintenance costs.

- Small size: Less shipping costs, easy to carry, light weight, easy to move.

Disadvantages:

- Limited cooling efficiency: Thermal management is inefficient, which impacts performance in high demand situations.

- Noise: If you choose a welding model with a fan, it can be noisy, which can be a problem in quieter work environments.

- Limited functionality: Can only weld and cut. And can only weld up to 5mm thickness.

Compared with traditional welding machines, which industries can laser welding machines be better suited for?

Laser welding machines are basically suitable for all industries that require welding, such as automobiles, aerospace, ships, electronics, jewelry, medical, etc. However, compared with traditional welding methods, laser welding machines are easy to operate, have high precision, beautiful welds, no requirements for filling materials, and high efficiency. They are especially suitable for industries that require high precision and beauty, such as medical equipment and jewelry, which are impossible for traditional industries.

| Welding Type | Laser Welding | TIG Welding | MIG Welding | SMAW Welding | EBM Welding | Gas Welding | Brazing Welding | PAW Welding | RSW Welding |

|---|---|---|---|---|---|---|---|---|---|

| Application | Automotive Medical Aerospace Electronics Jewelry Tool and Die Heavy Machinery | Pipeline Aviation Aerospace | Heavy Machinery Construction Pipeline Automotive | Construction Pipelines Shipbuilding Underwater Welding Heavy Machinery | Aerospace Shipbuilding Construction Electronics | Construction HVAC | Electronics Aerospace Automotive HVAC Construction | Tool and Die Aerospace Shipbuilding Turbine | Automotive Aerospace Construction Railway |