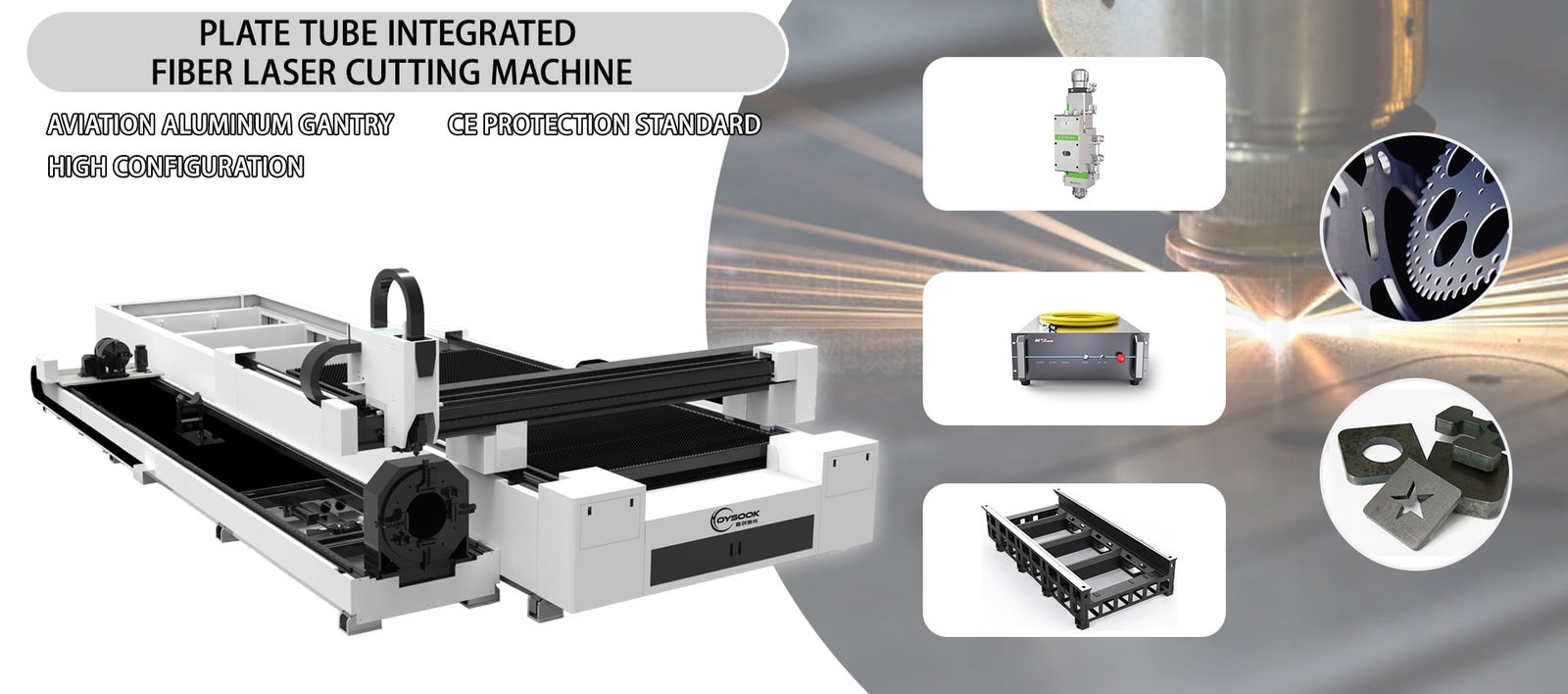

Sheet and Tube Cutting Machine

- Delivers high accuracy and clean cuts on a variety of materials ensuring high-quality results

- Reduced investment costs by eliminating the need for separate machines for plate and tube cutting

- Combines two functions in one machine, minimizing the floor space required

- Speeds up production cycles with its integrated design, leading to higher throughput

- Simplifies operations with a unified control system, making it easier for operation to manage

[maxbutton id=”1″ url=”#” text=”SEND INQUIRY” extraclass=”popup-field” ]

Description

Sheet and Tube Cutting Machine

High-capacity laser cutting machine for plate and tube production has become a cornerstone in medical device manufacturing, offering unmatched precision, reliability, and efficiency. These advanced machines are essential for producing intricate and high-quality components required in the medical field, including surgical instruments, implants, and diagnostic equipment. With their ability to cut biocompatible materials such as medical-grade plastics and stainless steel with exceptional accuracy, fiber laser cutters ensure that medical devices meet stringent industry standards.

Additionally, their capability to perform micro-scale cutting makes them ideal for creating complex and delicate parts used in minimally invasive surgical tools and high-precision medical instruments. By leveraging fiber laser cutting for orthopedic device production, manufacturers can enhance the quality and performance of medical devices, ultimately contributing to better patient outcomes and advancing healthcare innovation.

Advantages of the machine:

Economical and practical, efficient cutting, high-cost performance, small footprint, dual-purpose machine

- It integrates the functions of plate cutting and tube cutting, which is economical and practical, and can easily cope with diversified processing needs. It occupies a small area, reduces space constraints, is easy to operate, and saves worry and effort.

- The pneumatic clamping device firmly locks the pipe, and with the unique bed structure, heavy pipes can also be easily controlled, reducing the error caused by vibration during processing, and achieving high-precision cutting.

- The special bracket for pipes assists at multiple points and stably feeds the pipe to prevent long pipes from sagging and deformation, ensuring cutting accuracy and extending the service life of the chuck.

Advantages of CNC system:

- Error measurement: high accuracy, by comparing the command trajectory with the feedback trajectory, it is convenient for the debugging personnel to judge the difference in the servo gain of each spindle, thereby ensuring the motor motion accuracy and the actual accuracy of the workpiece

- Special steel centering: supports L-steel, channel steel, I-beam and other special steel centering, improving the cutting accuracy of special steel.

- Tube surface contour correction: For workpieces with stable deviations on the tube surface, it can effectively compensate for regular cutting deviations, reduce the precision requirements for raw materials, and reduce waste. 4. Single-sided centering can effectively solve the problem of the accuracy of the tube hole position and improve the accuracy of the hole position distance from the edge.

Reviews

There are no reviews yet.